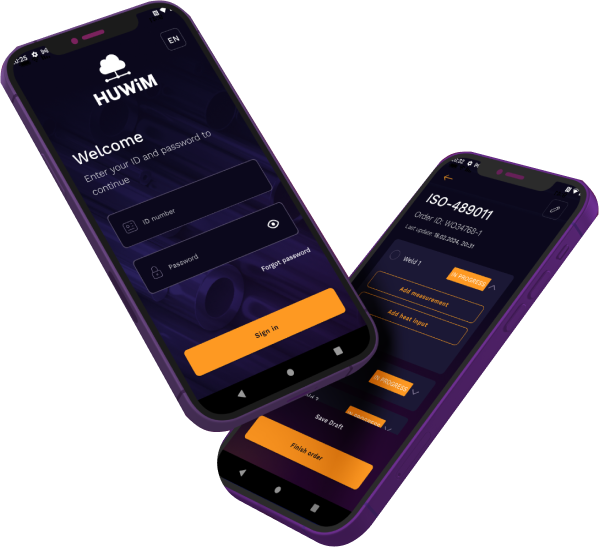

Welders can now perform Heat Input Checks directly through the HUWIM application, without the immediate need for an inspector on-site. This feature allows welders to verify their work and maintain the highest quality standards as they go, helping to avoid errors and deviations in real-time.

Welders can ensure they’re working within optimal parameters, preventing defects before they occur.

Access immediate validation, reducing the chances of mistakes and ensuring high-quality welds.

By using HUWIM, welders gain access to real-time data and insights that help them improve their skills over time. The application not only supports quality control but also acts as a learning tool, enhancing the welder’s knowledge and expertise.

Welders receive continuous feedback, helping them grow and perform at their best.

Access important data that aids in better decision-making and refined techniques.

The intuitive HUWIM Dashboard provides a comprehensive view of all welding jobs and progress. It ensures that every task is tracked and monitored, giving both welders and supervisors real-time insights into the status of each job.

Monitor each job in real-time.

Get updates on task completion and welding status, allowing for efficient planning and decision-making.

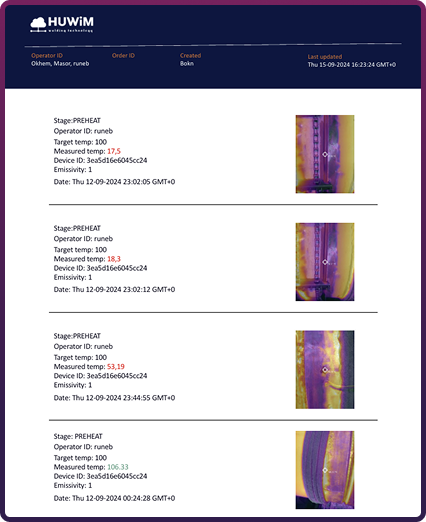

HUWIM simplifies the documentation process by automatically generating detailed reports. These reports can be easily retrieved for final documentation or provided to clients who require specific quality or progress updates.

Create detailed welding reports for final documentation or client requests.

Access important information whenever needed, streamlining both internal and external communication.

Welders can now perform Heat Input Checks directly through the HUWIM application, without the immediate need for an inspector on-site. This feature allows welders to verify their work and maintain the highest quality standards as they go, helping to avoid errors and deviations in real-time.

Welders can ensure they’re working within optimal parameters, preventing defects before they occur.

Access immediate validation, reducing the chances of mistakes and ensuring high-quality welds.

HUWIM isn’t just an application—it’s a powerful tool that streamlines welding operations, enhances quality, and increases efficiency. With comprehensive data tracking and real-time verification, you’ll ensure that every weld meets the highest standards, improving productivity and minimizing costly errors.

Ready to experience the future of welding quality control?

HUWIM is a real-time welding monitoring and verification application that helps welders and inspectors track every welding job, reduce errors, and generate automated compliance reports.

Yes! HUWIM is designed for all industries performing welding operations, from small workshops to large industrial projects, ensuring quality at every stage.

Absolutely. HUWIM helps businesses comply with industry standards such as ISO 3834-2 by offering structured reporting, verification, and quality management tools.

You can book a demo through our website to see how HUWIM works and how it can benefit your welding operations. Simply click the “Book a Demo” button to get started!